Mini Drone Design + Materials Showcase for Fictiv, Inc.

Project Length: 3 weeks

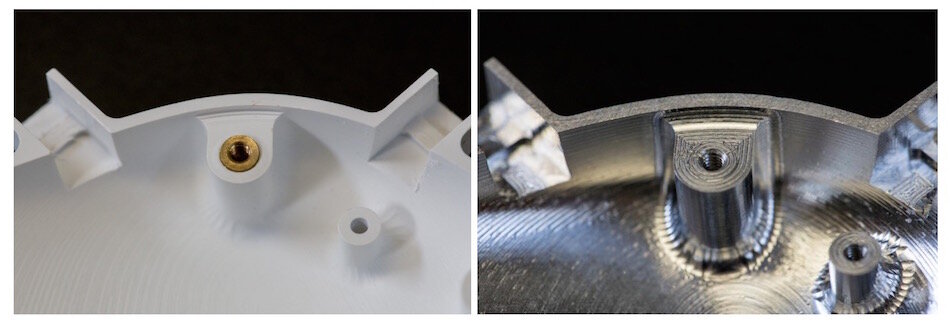

Focus Areas: Reverse Engineering, Rapid Prototyping, 3D Printing, CNC Machining, Design for Assembly

Materials: PLA, ABS, VeroClear, VeroWhite, ABS-Like, Rubber-Like, 6061 Aluminum, 360 Brass, Assorted Electronics

This project came out of a desire to develop a cohesive set of material samples for Fictiv’s first two manufacturing services: 3D printing and CNC machining. Initial requirements were vague, but the overall idea was that the samples needed to highlight the uses, advantages, and disadvantages of Fictiv’s standard materials for each process, as well as the processes themselves. In addition, individual samples should combine to form a functional product of some sort. After a quick brainstorm, the idea of a model drone was born, and in the three weeks that followed, the functional prototype was designed and built.

For a detailed deep-dive into the iterative design process, see this blog post.