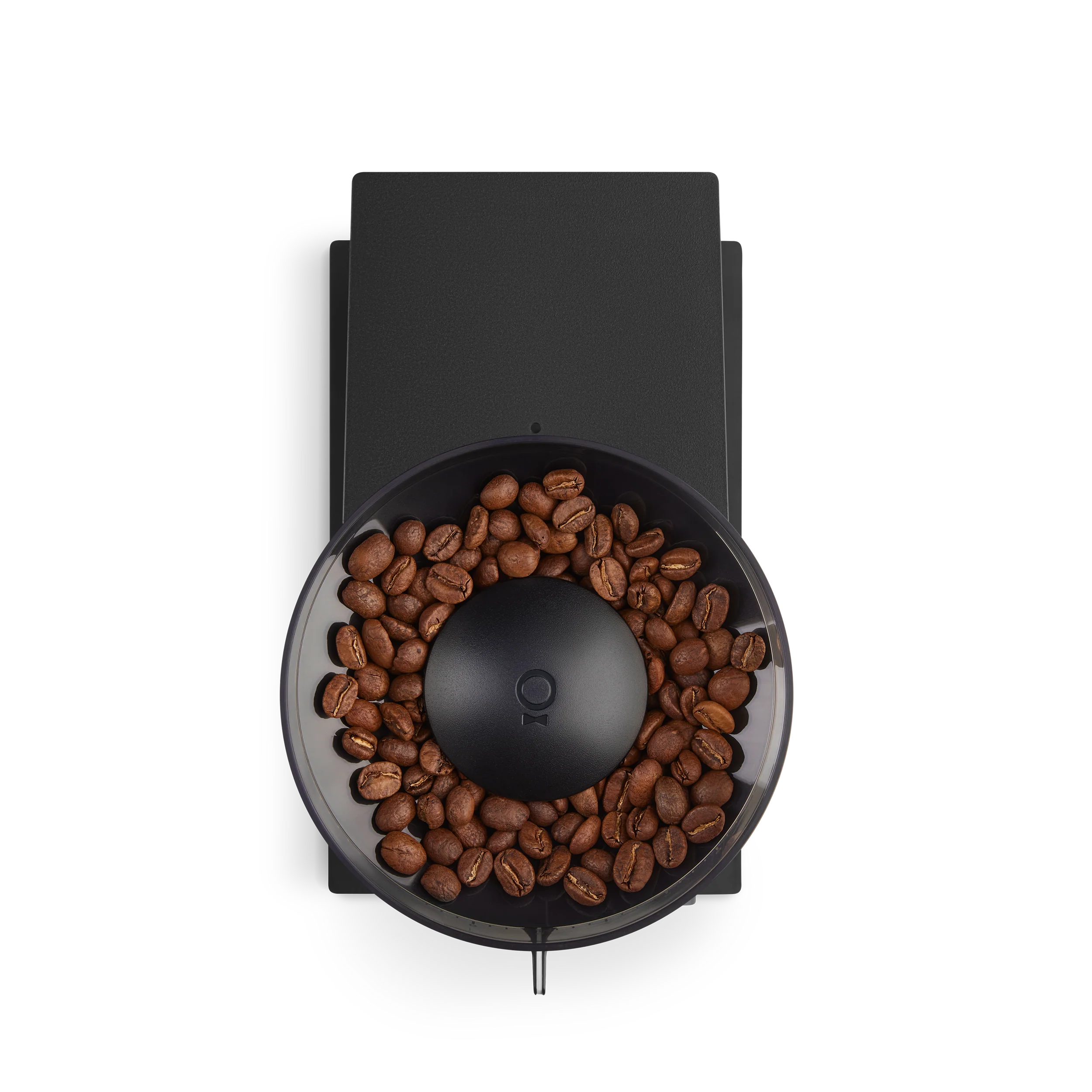

Design and development of the Opus Conical Burr Grinder for Fellow, Inc.

Program Length: 18 Months (Launched February 2023)

Focus Areas: Geartrain Design, Mechanism Design, Enclosure Design, Program/Product Management, CM Management

Materials: Engineering Plastics (PC/ABS, Nylon, Delrin), Hardened Stainless Steel Burrset

The Opus Grinder is Fellow’s first conical burr grinder, first grinder to support espresso, and my first product developed with the company. Fellow was early-stage, meaning each member of the product team was their own product owner, and wholly responsible for managing all activities leading up to launch. My role extended from PM to EPM to PD Engineer, and I managed the workstreams of 2 PDs, 1 EE, and 1 FW engineer.

Opus was a tough yet rewarding product to bring to life. Some highlights:

Proving out the powertrain design (motor, gears, burrs) was the main design challenge. Grinding for espresso demands a high-torque system (relative to its size) and it needed to last for thousands of cycles over a multi-year lifespan. The initial geartrain design had to be scrapped and redesigned to get this right, but the result is a workhorse that can even grind green beans.

Added thoughtful design touches like dosing compartments in the hopper lid, spouted catch and espresso dosing cup.

Maintained a close relationship with our CM in China during all phases of development. Could not travel to the factory due to Covid so almost daily communication was required to keep up to date on project progress.

First time navigating the compliance realm of kitchen appliances; worked with cert labs in China to meet safety and electrical specs for 8 SKUs around the world.

Successful launch, mostly positive customer reception and reviews, surpassed volume targets for year 1 post-launch.